|

|

|

|

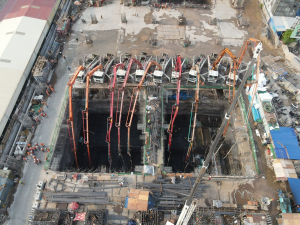

Project Highlights Pavilion Damansara Heights (Phase 1) Scope of Works: foundation, retaining wall and basement works

The project site is located within Damansara Heights between 2 MRT stations - Semantan and Pusat Damansara. Phase 1 footprint alone is 9.573 acre. The contract entails the removal of existing foundation of demolished buildings as well as the construction of bored pile foundation, retaining wall system and 8- level basement. The basement is one of the largest and deepest ever constructed in the region with a massive floor plate area of approximately 300,000m2. The total depth from existing ground level to lowest slab is approximately 31m excluding the deepest lift core construction which required another 10m depth of temporary shoring works. Approximately 900 points of bored piles with diameters ranging from 750mm to 3,000mm were constructed in Kuala Lumpur Kenny Hill formation. Existing surrounding dense environment and Sprint Highway had precluded the construction of deep basement using conventional open cut method and tie back system using soil nail/ground anchor due to encroachment issue by site boundary. Top-down construction and semi top-down construction methods where floor slabs are utilised to strut against the deep basement wall while excavating downwards are adopted. The top-down work sequence adopted alternate basement permanent floor (B3, B5 & B7) as strutting slabs against the contiguous bored pile (CBP) basement wall. Sequence took into consideration of basement slab (including temporary openings to facilitate earth removal and concreting works of lower floors) and CBP wall in modelling, design, logistic and construction work aspects. Naga 3 Integrated Entertainment Complex, Phnom Penh, Cambodia Scope of Works: Piling, Pile cap, Diaphragm Wall, Basement & Associated Works

The foundation and substructure package entails construction of bored pile foundation, retaining wall system and 4-level of basement, within a demanding urban environment in the heart of Phnom Penh. The project site was divided into three main sections, i.e. Tower 1 (Section 2), Tower 2 (Section 3) and Tower 3 (Section 1). Nearly 800 bored piles, ranging from 1.0m to 2.0m in diameter and up to 64.5m in length, were installed. The project posed significant challenges, requiring drilling in a congested urban area and socketing piles into extremely hard rock. The site’s soil profile includes silt, sand, and stiff clay, underlain by weathered sandstone. Rock layers were encountered at depths of 30m to 40m, with increasing strength at greater depths, some exceeding 100MPa. Following the completion of piling works, five expansive basement levels were constructed, with slab areas ranging from 11,000m2 to 15,000m2. A semi top-down construction method was adopted, starting with the ground floor slab to reinforce retaining walls before excavation. The basement was then built in a controlled top-down sequence from Level B1 to B4, allowing simultaneous excavation and construction. This approach optimised time and ensured structural stability by reinforcing each level during excavation, minimising ground movement and structural stress. A peak workforce of around 450 skilled workers was mobilised on-site during the most critical phases. A key standout achievement of the basement construction was the record-breaking concrete pour for the 4m-thick raft foundation of Tower 1, integral to its earthquake-resistant design. This large-scale operation involved placing 6,000m3 of concrete at Level B4, covering an area of 1,600m2, supported by nine pump trucks and over 700 concrete deliveries. More than 200 professionals and workers collaborated in shifts to expertly manage the complexities of this large-scale continuous pour. The successful project completion highlights expertise in bored pile construction under complex soil conditions and proficiency in top-down construction. Despite disruptions from the COVID-19 pandemic, the team managed workforce coordination, health protocols, and supply chain challenges, showcasing resilience, adaptability, and engineering capability. Immigration, Customs and Quarantine Complex (ICQC) for Rapid Transit System Link (RTS Link) between Johor Bahru and Singapore Scope of Works: Bored piling works

The project entails the construction of over 250 bored piles with diameter and length ranging from 0.75m to 2.5m and 40m to 100m respectively. Of these, over half are large piles measuring 1.8m in diameter onwards and up to the length of 100m. The piles were installed in sandy soil conditions without embedment into support rock. This completion of this project reinforces the Group’s ability to construct large-diameter deep depth piles in stringent quality control environment. This project successfully showcases not only the capability of our fleet of large-capacity drilling rigs (Bauer BG50, BG40 and BG39), but also the competence of our team in providing peak efficiency whilst upholding the highest quality, health and safety standards throughout the project execution. Sungai Besi-Ulu Kelang Elevated Expressway (SUKE) Package CA3 Scope of Works: foundation, substructure and ancillary works

The contract entails the construction of over 1,000 bored piles and 50 caisson piles for package CA3 starts from CH. 4200 to CH. 7800 with total length of approximately 5.2 km in Alam Damai, southeast of Kuala Lumpur. This project is of particular engineering importance as it showcases the pioneering expertise in large diameter hard rock drilling using down-the-hole (DTH) hammer in challenging rock formations. With percussion boring, the DTH technique, compared to conventional rotary drilling, has been proven to be significantly more efficient in hard rock areas. DTH hammer was used to drill 200 points of large-diameter bore holes for the project (with 1,200mm∅ and 1,500mm∅ casings through hard granite strata). MAS Building Annex Redevelopment Scope of Works: foundation, retaining wall and basement works

A 37m deep excavation was carried out to construct a 6-level underground basement at Jalan Sultan Ismail in downtown Kuala Lumpur. On top of being situated very close to the Raja Chulan monorail track, the site is located next to a busy road with heavy traffic, high-rise buildings and the existing MAS Building. The project demanded control of minimum lateral wall movement, minimum soil settlement, and timely completion in a very limited site area of about 2,400m2. Major works for phase one included demolition of the front podium and removal of existing 450mm∅ CBPs. Second phase involved installation of new CBPs ranging from 600mm∅ to 1,350mm∅, of an average depth of 45m and 3,000mm∅ foundation bored piles of an average depth of 70m. The semi top-down construction method with kingposts was adopted, in place of installation of temporary steel struts and walers to support deep excavation. 6 basement slabs were constructed and the volume of earthwork was approximately 82,000m3. |